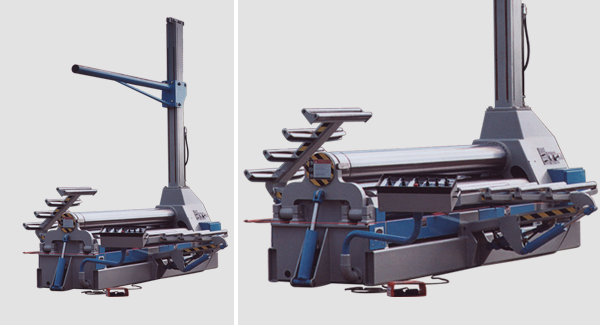

4 ROLL DOUBLE PINCH PLATE BENDING MACHINES

WDM - 430 SERIES

Imagine rolling any material—thick or thin—into a perfect cylinder every time, without shimming or rework. Today, I’m thrilled to unveil the WDM 430 Series plate roll, a game-changer that takes our legendary 4-roll design to the next level. Let’s dive in!

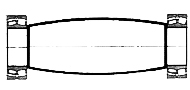

To roll a perfect cylinder, your material needs to be pinched with even pressure across the entire width. If there’s more pressure on the ends, you get a barrel-shaped cylinder—tight at the edges, gapped in the middle. If the center is pinched harder, you get an hourglass shape—tight in the middle, loose on the ends.

Here’s why that happens: most plate rolls are supported on the ends. So when you feed material into the machine, the force causes the rolls to deflect or bend. To compensate, the industry crowns the rolls—making them larger in the middle so they even out under pressure.

But here’s the problem: different materials deflect the rolls differently. A ¼-inch plate causes more deflection than, say, 20-gauge sheet. If your machine is crowned for ¼-inch, anything thinner rolls into an hourglass. If it’s crowned for thin material, heavier plate turns into a barrel.

To work around this, operators sometimes shim the rolls—adjusting pressure with cardboard etc. to get a perfect shape. But shimming is tedious, time-consuming, and not ideal for shops rolling a wide range of materials.

Enter the WDM 430 Series. Our patent pending “Passive Crown System” eliminates deflection issues. The pinch and bending rolls adapt to match the top roll’s deflection, whether you’re rolling 20-gauge or ¼-inch steel. No crowning, no shimming—just perfect cylinders every time. You can roll anything from thin sheets to max capacity with zero defects.

This isn’t just tech for tech’s sake. The WDM 430 Series boosts your shop’s efficiency:

- Versatility: Roll any thickness or width over 12 inches up to max capacity.

- Speed: No shimming means faster throughput.

- Precision: Say goodbye to barrel or hourglass shapes.

Standard Features of 430 Series

- Automatic compensation for roll deflection creating the following features:

- No Crown required in the rolls

- The ability to roll any thickness and width of material up to max capacity without any roll deflection symptoms in the workpiece

- No shimming required to correct “hour glass” shaped cylinders resulting from too much roll crown

- No shimming required to correct “barrel” shaped cylinders resulting from not enough roll crown

- Flame Hardened and Polished 1045 Carbon Steel Rolls

- LSHT type hydraulic drive motor with high volumetric and overall efficiency

- Hydraulic driven rolls which provides instant start, stop, and reverse

- Two roll drive

- NEMA 12 control cabinet with fused power supply

- Electrics meet NFPA 79 Specifications

- 230/460-volt 3 phase 50/60 hertz electrics (specify voltage when ordering)

- Variable Frequency Drive on main motor

- Infinitely variable rolling speed up to 22 FPM

- Electronic overload protection

- SKF spherical roller bearings on all main bearings

- Safety cable around perimeter of machine

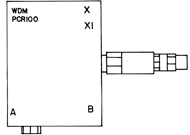

- Beta 4.2 rolling console control. Pushbutton control of main functions and 3 digital readouts to show the position of the 3 lower rolls.

- Rolls driven directly or through planetary gear type speed reducers

- Machine sets directly on level floor

- Ability to roll symmetrical steel sections without additional attachments

- Hydraulic operated drop end support

OTHER OPTIONS AVAILAVLE INCLUDE

- Cone Attachment with roller “snubber”

- Side Supports

- Overhead Support

- Ejector

- Dual Footswitch

- Pre 4.2 (preset) Control

- 4R-AP (CNC) Control

- Light Curtains and Hard Guarding

- OTHER SPECIAL OPTIONS AVAILABLE UPON REQUEST

4 ROLL DOUBLE PINCH PLATE BENDING MACHINES

WDM - 403 SERIES

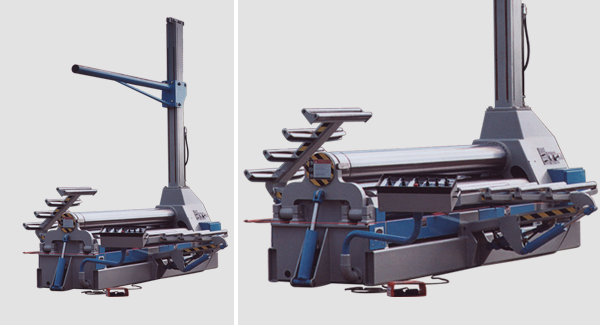

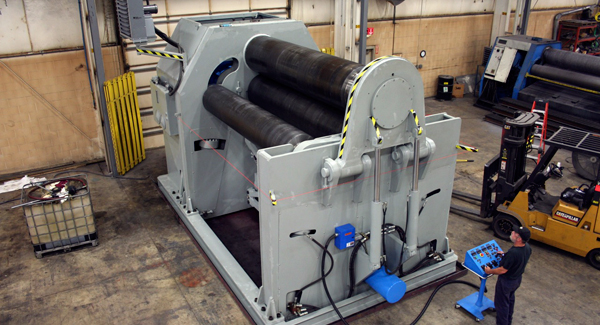

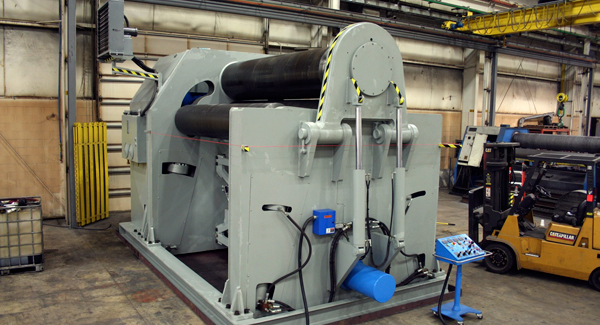

403-6-6 (7/32" x 6') Standard machine equipped with optional dual foot pedal for roll rotation. The machine as equipped with standard features is a very functional machine and does not require any options to roll cylindrical workpieces.

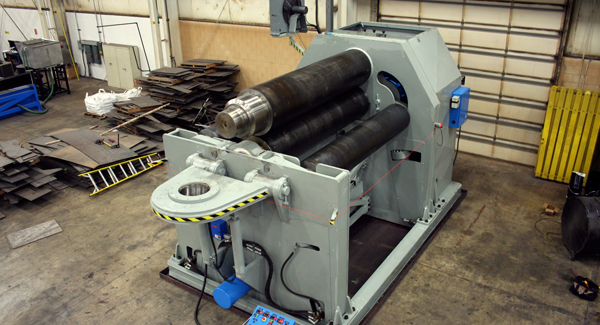

403-7-6 Equipped with 424-3 machine mounted preset type control, dual foot pedal for roll rotation, and cone attachment.

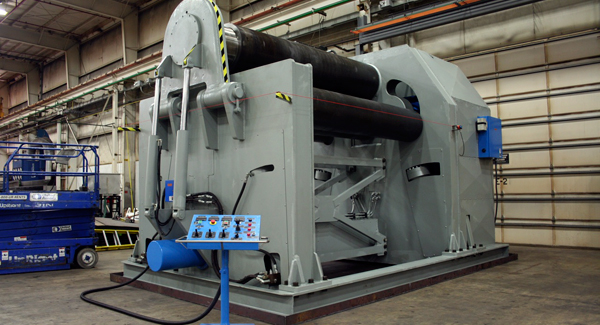

403-12-10 (1/2" x 10') Used in plant which manufactures steel stacks, sewage processing eqpmt., and grain/dust handling eqpmt. Equipped w/ flame hardened rolls, 2 dual-purpose side supports, overhead support, dual roll rotation foot pedal, and 423-3-LP6 control.

403-12-10 (1/2" x 10') Used in plant which manufactures steel stacks, sewage processing eqpmt., and grain/dust handling eqpmt. Equipped w/ flame hardened rolls, 2 dual-purpose side supports, overhead support, dual roll rotation foot pedal, and 423-3-LP6 control.

403-12-10 (1/2" x 10') Used in plant which manufactures steel stacks, sewage processing eqpmt., and grain/dust handling eqpmt. Equipped w/ flame hardened rolls, 2 dual-purpose side supports, overhead support, dual roll rotation foot pedal, and 423-3-LP6 control.

3” x 10’ capacity

3” x 10’ capacity

3” x 10’ capacity

3” x 10’ capacity

3” x 10’ capacity

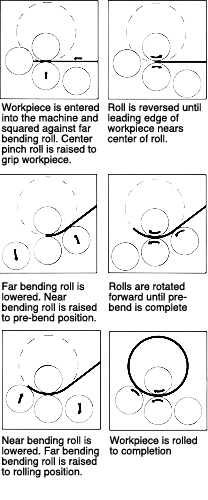

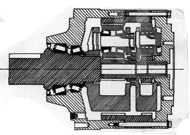

The 403 Series 4-roll double pinch plate bending machine is in a sense a 3-roll initial pinch plate bending machine with an extra bending roll on the front side of the pinch rolls. The advantage of this type of machine is that it enables the operator to roll the workpiece from the leading to the trailing edge with minimal and usually negligible flats. As a rule of thumb, the flats are less than 1 1/2 to 2 times the work piece thickness. This can be accomplished in a single pass without turning the workpiece. See forming procedure for details.

STANDARD FEATURES

Rolls - The heart of the WDM 4-roll plate bending machine is the rolls themselves. These rolls are machined from 1045/50 steel bars or forgings. They are crowned to compensate for deflection and supported on sealed, self aligning, spherical bearings requiring minimal maintenance. These rolls are sized according to the load imposed during the rolling cycle, making the machine more compact and streamlined than before without affecting the capacity.

Rolls - The heart of the WDM 4-roll plate bending machine is the rolls themselves. These rolls are machined from 1045/50 steel bars or forgings. They are crowned to compensate for deflection and supported on sealed, self aligning, spherical bearings requiring minimal maintenance. These rolls are sized according to the load imposed during the rolling cycle, making the machine more compact and streamlined than before without affecting the capacity.

Roll support and adjustment - The bearings that hold the rolls are supported on a set of master

Roll support and adjustment - The bearings that hold the rolls are supported on a set of master

and slave hydraulic cylinders with very effective seals and

travel in a radial path (bending) and a straight path (pinch).

Restoring parallelism of rolls - Restoring parallelism of rolls is accomplished by a special

Restoring parallelism of rolls - Restoring parallelism of rolls is accomplished by a special

valve arrangement designed by WDM which is activated

when the roll is lowered to the bottom and held momentarily

until all movement ceases. Roll is then parallel with top roll.

Control of Rolls - The hydraulic circuit is fitted with a half-turn valve that allows all adjustable rolls to be angled for cone rolling, etc. The control also contains motor starting switch, function speed. Restoring parallel ism of rolls control, pinch roll pressure regulator, and indicator gauge.

Control of Rolls - The hydraulic circuit is fitted with a half-turn valve that allows all adjustable rolls to be angled for cone rolling, etc. The control also contains motor starting switch, function speed. Restoring parallel ism of rolls control, pinch roll pressure regulator, and indicator gauge.

Roll position indicators - These very practical and trouble free roll position indicators consist of an etched dial and pointer located on main housing facing operator's position. Various other indicators are available.

Roll position indicators - These very practical and trouble free roll position indicators consist of an etched dial and pointer located on main housing facing operator's position. Various other indicators are available.

Roll drive - The top and bottom center rolls are driven by individual low speed, high torque type hydraulic motors with very high volumetric and overall efficiency. The motors are coupled to rolls with rigid couplings and planetary and/or spur gear type speed reducers. (4" & 5" roll machines do not have speed reducers.) Top and bottom roll speeds are hydraulically synchronized and equalized. This drive type provides highly efficient transfer of torque.

Roll drive - The top and bottom center rolls are driven by individual low speed, high torque type hydraulic motors with very high volumetric and overall efficiency. The motors are coupled to rolls with rigid couplings and planetary and/or spur gear type speed reducers. (4" & 5" roll machines do not have speed reducers.) Top and bottom roll speeds are hydraulically synchronized and equalized. This drive type provides highly efficient transfer of torque.

Control valves - The control valves are manual actuation type and mounted on main machine housing. This standard feature gives excellent feel and feathering capability to the operator's finger tips. Many other controls are available.

Control valves - The control valves are manual actuation type and mounted on main machine housing. This standard feature gives excellent feel and feathering capability to the operator's finger tips. Many other controls are available.

Hydraulic system - The hydraulic reservoir is an integral part of the machine frame which helps dissipate system heat. This and careful attention to efficiency of components keeps the hydraulic system cool. The

Hydraulic system - The hydraulic reservoir is an integral part of the machine frame which helps dissipate system heat. This and careful attention to efficiency of components keeps the hydraulic system cool. The

pump, valves, and other hydraulic components are sized and designed with maximum efficiency and function in mind.

Speed control - The speed of the entire system is controlled via a flow control knob located on the main housing near the operator's station. This knob controls the roll rotation and the adjustment speeds.

Speed control - The speed of the entire system is controlled via a flow control knob located on the main housing near the operator's station. This knob controls the roll rotation and the adjustment speeds.

Individual speed control is available as an option on smaller Frame machines and standard on larger machines.

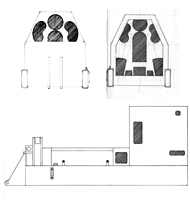

Frame - All this is housed in a compact, streamlined, fabricated, and machined steel frame composed of steel plates and robust structural sections.

Frame - All this is housed in a compact, streamlined, fabricated, and machined steel frame composed of steel plates and robust structural sections.

Safety Cable - A safety cable on three sides of the machine allows anyone to stop the machine by tripping the wire. Its switch incorporates a feature which makes it impossible to start the machine unless the cable is installed with proper tension. (Light curtains and safety mats are available as optional accessories.)

Safety Cable - A safety cable on three sides of the machine allows anyone to stop the machine by tripping the wire. Its switch incorporates a feature which makes it impossible to start the machine unless the cable is installed with proper tension. (Light curtains and safety mats are available as optional accessories.)

Finish - Machine is finished with V.O.C. compliant haze gray epoxy and safety blue enamel.

Finish - Machine is finished with V.O.C. compliant haze gray epoxy and safety blue enamel.