WDM 4 ROLL CONTROL OPTIONS

WDM Plate Rolls have a circuit board which contains the necessary control hardware for all available options and permits more efficient communication through smaller wires, which results in a smaller control cord. These control cords are prewired with the proper plugs so they can be conveniently changed if damaged, and all controls are plug-and-play so they can be easily upgraded at anytime. The Footswitch option is also plug-and-play, and is provided with a selector that allows the operator to choose between Rotation Forward/Reverse and Pinch Roll Up/Down. Roll Trim is operated from the control panel, and the 4R-AP includes a Pinch Pressure display in addition to the Pinch Pressure Control located on the drive housing. WDM Plate Rolls also utilize a variable frequency drive (VFD) for the main motor, which allows precise control of machine speed.

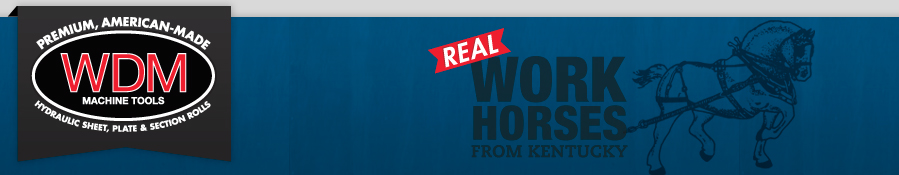

BETA 4.2

Push buttons to control:

- Control

- Near roll

- Far roll

- Drop end

- Emergency stop

- Pinch roll

- Roll rotation

Selector switch to control:

- Roll trim

- Rotation reroll

- Cycles-Warmup, Drop End Open/Closed, Tack

Dial to control system speed.

Digital readout to show position of:

- Near roll

- Pinch roll

- Far roll

— Free standing rolling console

— NEMA 12 Fiberglass enclosure

— Stainless steel hand rail

— Receptacle for control cord

Recommended use, Job Shops and part batches up to 10 pieces.

PRE 4.2

Push buttons to control:

- Control

- Drop end

- Emergency stop

- Far roll gauge position

Variable speed joysticks to control:

- Near roll

- Pinch roll

- Far roll

- Roll rotation

Selector switches to control:

- Roll trim

- Rotation reroll

- Set point 1 mode

- Set point 2 mode

- Normal mode

Digital readout to show position and control:

- Near roll (2 set points)

- Pinch roll (2 set points)

- Far roll (3 set points)

- Roll rotation (3 set points)

— Free standing rolling console

— NEMA 12 enclosure

— Stainless steel hand rail

— Receptacle for control cord

Recommended use, this popular control provides just enough automation to greatly speed through put performance, and accuracy. It is easily programmed and can be used as manual or preset type control. In many cases this control increases roll performance 500% or more and is usually all the automation that is required. This control is recommended for part batch sizes from 3 to 100 pieces or more.

4R-AP

This CNC control is designed for high volume production. The material is hand-fed, (automatic infeed as well as various levels of complete automatic rolling cells are avail- able) and it completes all forming functions automatically. You can run it in the follow- ing modes: Warm-Up to get the machine to operating temperatures, Drop End Open for full circles, Drop End Close for segments, and Tack for positioning part to tack weld on the machine. This control can be used in Manual, Preset, or Auto modes and has a 1,000 part memory storage. It is recommended for part batch sizes of 50 plus pieces. All controls are plug and play, dependent on options, and can be upgraded at any time.

Push buttons to control:

- On/Off

- Drop end

- Emergency Stop

- Pause/SP override

Joysticks to control:

- Near roll

- Pinch roll

- Far roll

- Roll rotation

Selector switches to control:

- Roll trim

- Rotation reroll

- Cycle - warmup drop end open/close, or tack

Dial to control system speed.

Panasonic HMI Functions:

- Display readouts of all roll positions

- Program setpoints

- Name parts

- Select mode (Auto, Preset, Manual)

- Mode indicator light

Footswitch to control:

- Cycle start

- Rotation forward

- Pinch roll up

- Indicator light to show Cycle Pause

- Free standing rolling console

- NEMA 12 enclosure

- Stainless steel handrail

- Receptacle for control cord

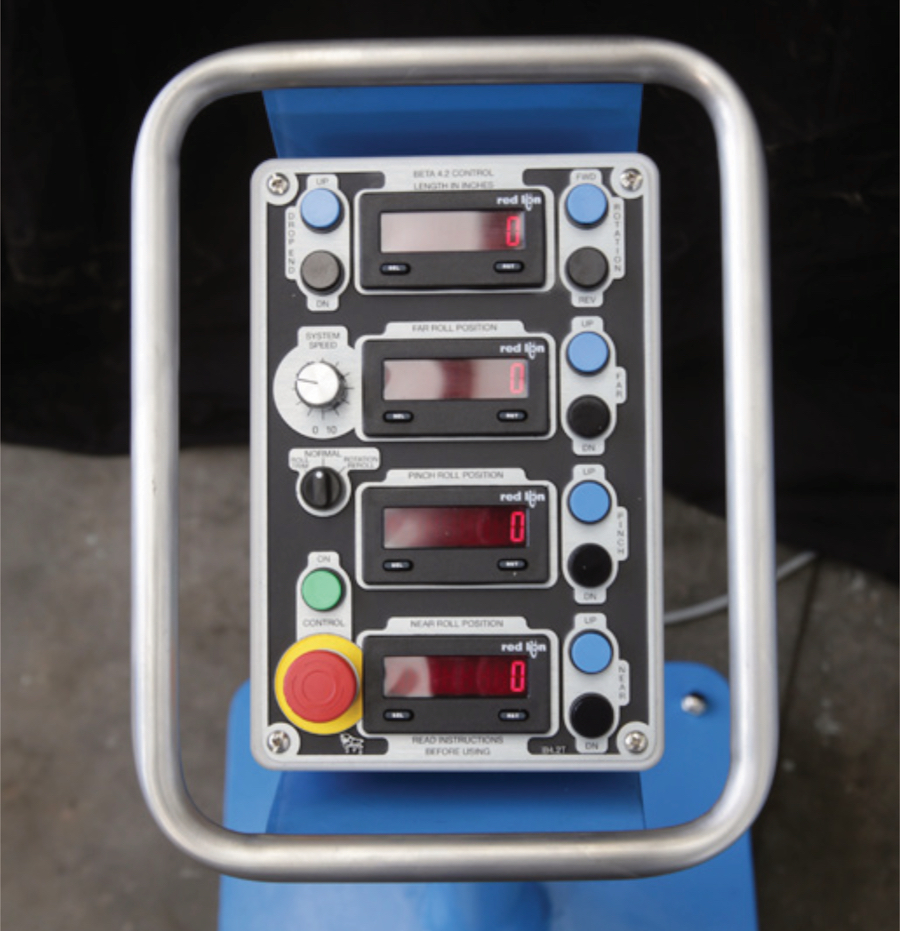

FS 2.2

This is the double footswitch option.

Selector to control function:

- Pinch roll up/down

- Rotation Forward/Reverse

- Off

- Compatible with all controls