PR Series

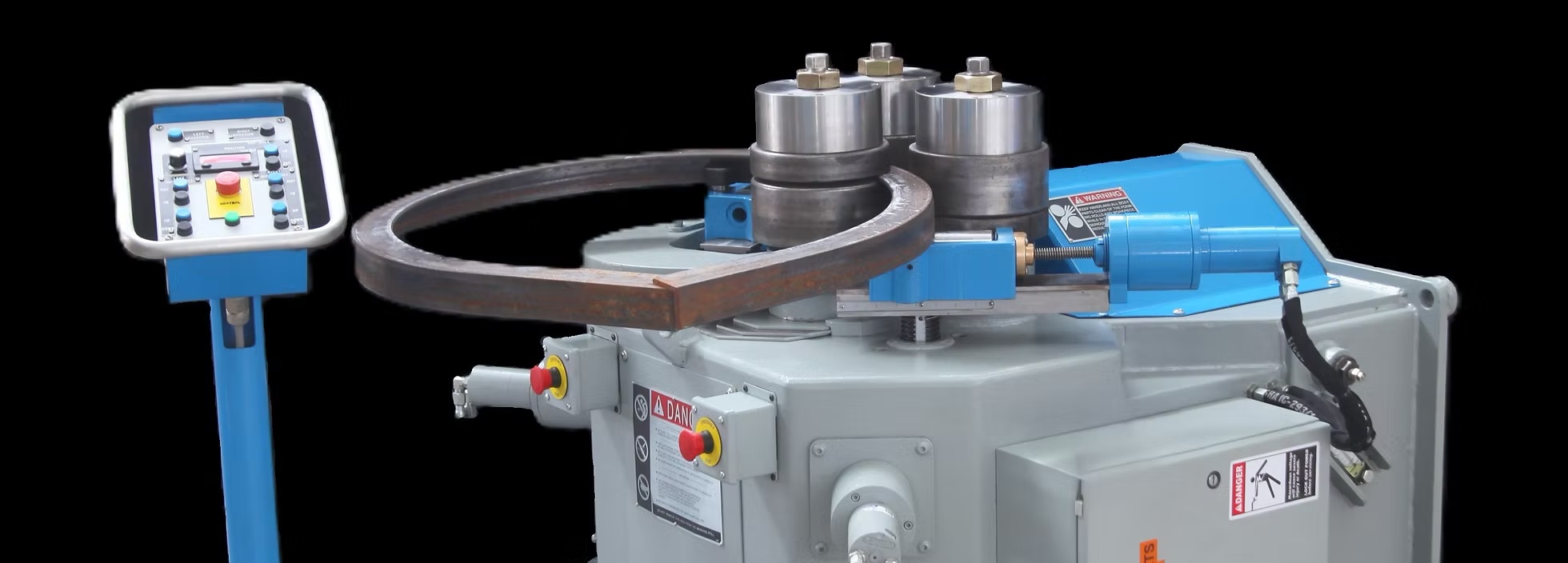

Being in the metal industry you understand the demand there is for angle, tubing, pipe, channel, I-beam and other profiles in the manufacturing industry. Whether you are making a tanker trailer or a spiral staircase handrail the ability to roll profiles is essential to your business. WDM knows the demands that are placed on you to provide your customers with consistent, quality parts and products which is why we offer the PR Series. The PR Series takes WDM’s 35 years of knowledge making durable roll bending machines and combines that with a high production mindset. What you get is a heavy duty 3-roll pinch pyramid style angle roll where the 2 bending rolls are stationary and the top roll is the only moving variable. By limiting the die variables to just one setting you drastically increase the repeatability you can achieve even if the machine is operated by several different operators. The PR Series is highly recommend for large production applications where consistency is required from piece to piece.

Standard Features

- Unitized steel construction

- Flame hardened steel shafts and arbors

- Total hydraulic operation

- Instant start/stop/reverse

- Infinitely variable speed from 0-22FPM

- 1 set universal dies; rolls:

- Angle leg in and out

- Tee bar leg in and out

- Flats on edge and on flat

- Square and small rounds

- Accurately machined and hardened dies

- 3 roll drive (all machines except 4 roll)

- Roving pendant control

- DRO to show roll position

- Electrics to NFPA specifications

- 24VDC control circuit

- Safety stop/emergency stop mushroom buttons

- Overload protection

- TEFC main motor

- Quiet integrated hydraulic system

- Painted haze grey epoxy and blue enamel

- sealed spherical roller bearings on all main points

- Non-lube, minimum maintenance technology throughout

- Heavy gear drive with very strong efficient tooth profile, most gears cut in our own shop.

- Made in USA

Options

- Control upgrade

- Special dies

- Special guides

- Overhead supports

- Non-electric version

- Special electrics

- Special paint

- High speed version

Positioning

The rollers on the PR series can be configured to bend in a vertical or horizontal position.

PR2.2

Standard control with a 4-way joystick for rotation and adjustment and a DRO showing top roll position.

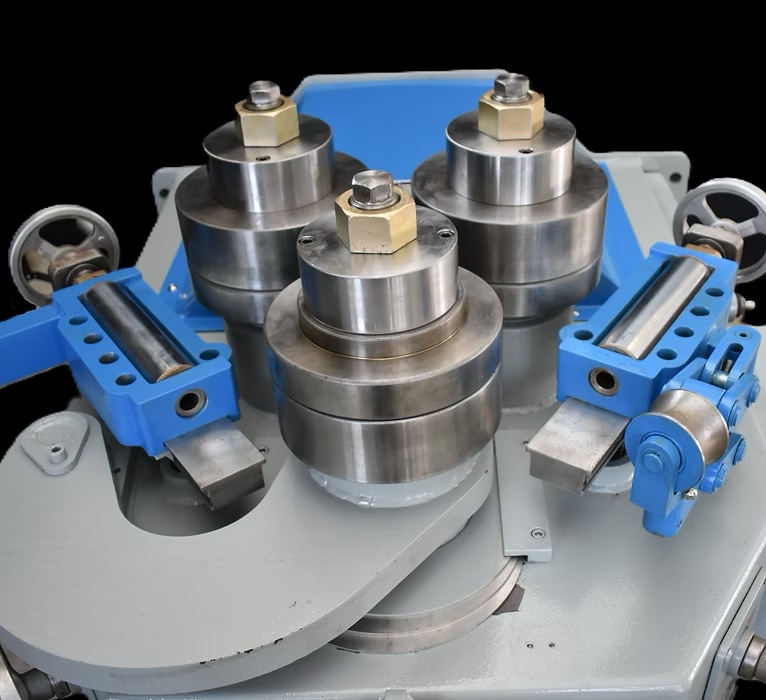

Dies/Guide Rolls

Hardened and ground universal rolls/dies are telescoping to allow for optimum adjustments with main cap screw. These rolls can be used to roll angles leg in/out, tees leg in/out, flat bars on flat and on edge, square bars, and small rounds.

Optional rolls are available for:

- Round tube

- Large rounds

- Channel on web and flange

- I-beam on web and flange

- Square and rectangle structural tube

- Forming half pipes and channels

- Earth mover tire lock rings

- Profiling and radiusing half pipe from flat strip, stainless and carbon steel.

- Aluminum extrusions for manholes and industrial louvers

- Formed steel and stainless steel sections for man holes and similar applications

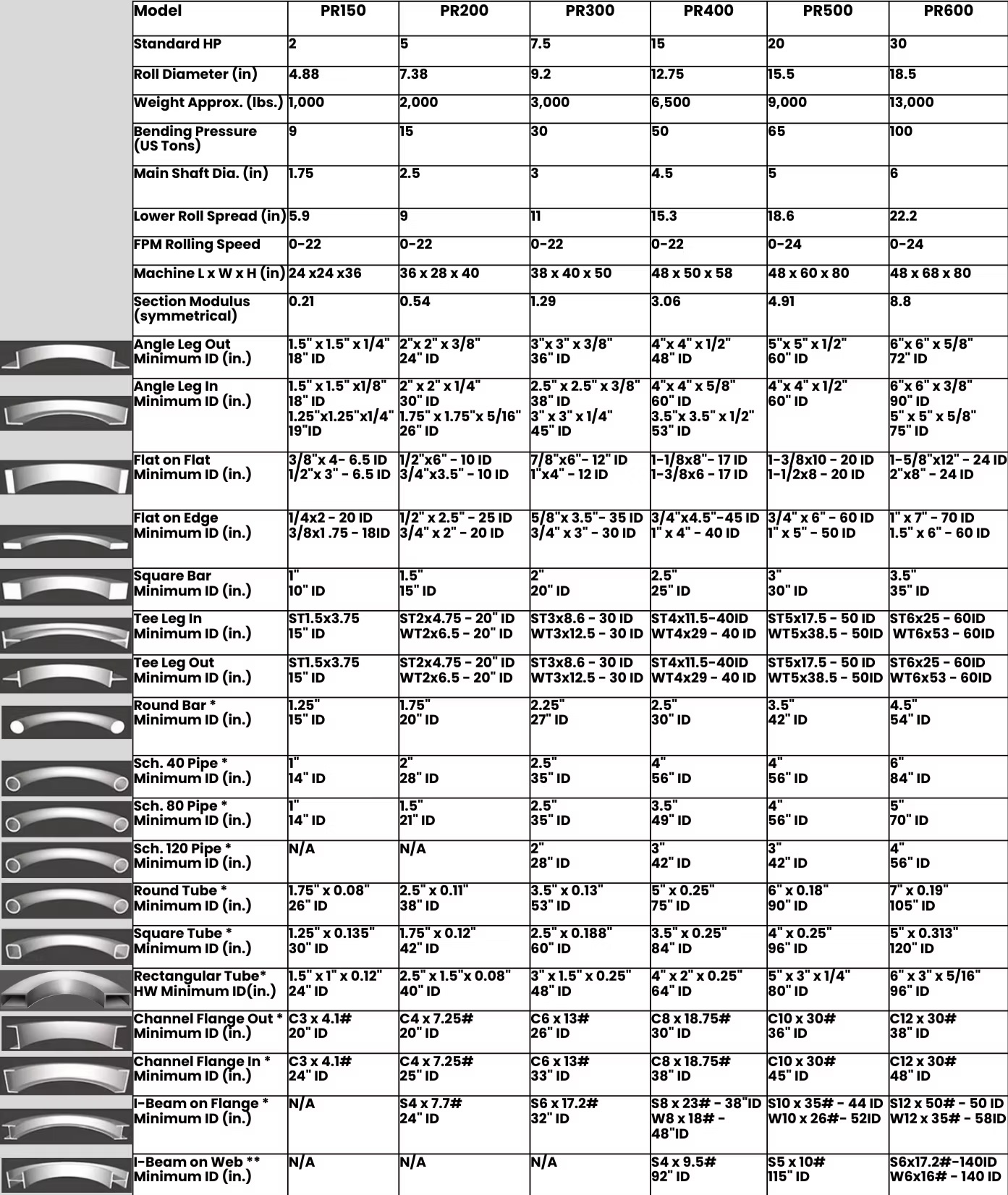

Machine Specs and Capacities