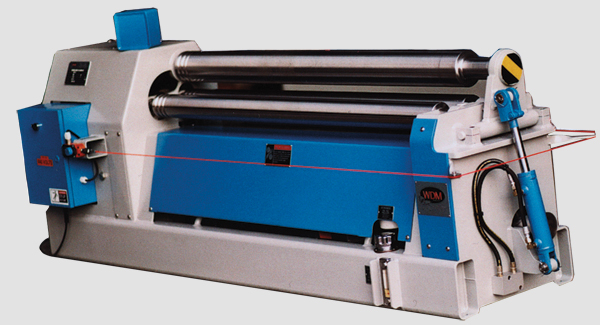

HYDRAULIC INITIAL PINCH PLATE BENDING MACHINES WDM - K SERIES

K-6-5 (1/4" x 5') Standard machine with special circular grooves and optional foot pedal FP.

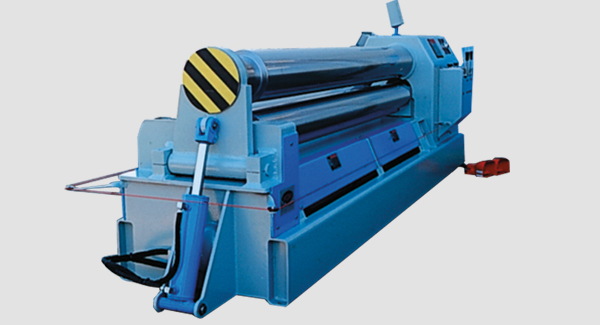

K-6-5 (1/4" x 5') plate bending roll. Showing rear side of machine.

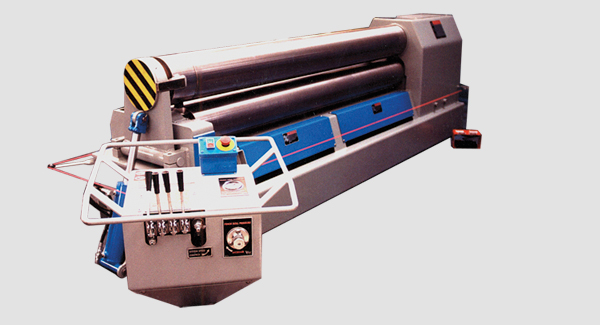

K-10 viewed from the drop end.

K-10-8 (13/32" X 8' with optional swinging console SC.

The WDM hydraulic initial pinch plate bending machine; models K-5 to K-19 are well designed, robust machines that feature a wedge actuated pinch roll positioning system. This provides for an accurate and parallel pinch roll position. The rear bending roll is positioned with heavy duty master and slave hydraulic cylinder arrangement. The accurately machined rolls turn on sealed spherical roller bearings with extended maintenance period of five years or more, in most cases. The heavy fabricated steel main frame contains a hydraulic reservoir for a quiet integrated hydraulic system. In designing the system, much attention is given to the efficiency of components which results in a cool operation. The standard manual hydraulic valves provide an excellent feel of the forming operation. The simple analog dial pointer (clock) style roll position indicator is very practical and trouble free. If however you prefer a more sophisticated machine we offer many options and enhancements in control styles and position indication. We even offer a fully automatic PLC type control. If you have a special need beyond this we are glad to accommodate it.

SOME OUTSTANDING FEATURES

Hydraulic reservoir is integrated into the structural frame which helps dissipate the heat. Notice the convenient location of oil fill and level temperature gauges.

Hydraulic reservoir is integrated into the structural frame which helps dissipate the heat. Notice the convenient location of oil fill and level temperature gauges.

The cone attachment consists of an indexable and replaceable hardened steel nose mounted on a bronze or composite - bushed steel sleeve which slides onto the reduced diameter portion of the top roll next to the drop end. It is locked into position by the drop-end and removed when not rolling cones. Heavy duty cone attachments are available for shops doing large amounts of cone rolling.

The cone attachment consists of an indexable and replaceable hardened steel nose mounted on a bronze or composite - bushed steel sleeve which slides onto the reduced diameter portion of the top roll next to the drop end. It is locked into position by the drop-end and removed when not rolling cones. Heavy duty cone attachments are available for shops doing large amounts of cone rolling.

Notice simple clean lines and robust housing which contains the drive system and hydraulic components.

Notice simple clean lines and robust housing which contains the drive system and hydraulic components.