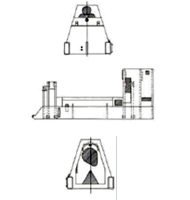

3 Roll Pinch Pyramid Hydraulic Plate Bending Machines

The 5, 6 and 7" hydraulic initial pinch pyramid rolls have been designed with high performance and streamlined economy in mind. These machines are excellent for fabricators, welding shops, maintenance shops and production applications.

STANDARD FEATURES

Forming Rolls - Bars of 1045 steel machined into the forming rolls. These are crowned to compensate for the deflection caused by the forming pressures. These are supported on large capacity, self aligning spherical roller bearings.

Forming Rolls - Bars of 1045 steel machined into the forming rolls. These are crowned to compensate for the deflection caused by the forming pressures. These are supported on large capacity, self aligning spherical roller bearings.

Hydraulic cyclinders - A pair of master and slave hydraulic cylinders arranged to raise and lower the 2 adjustable lower rolls in a radial path.

Hydraulic cyclinders - A pair of master and slave hydraulic cylinders arranged to raise and lower the 2 adjustable lower rolls in a radial path.

Hydraulic circuit - Installed valves in the hydraulic circuit with half-turn knobs which allow the operator to angle the rolls for rolling conical shaped work pieces.

Hydraulic circuit - Installed valves in the hydraulic circuit with half-turn knobs which allow the operator to angle the rolls for rolling conical shaped work pieces.

Valve arrangement - Special valve arrangement designed so rolls can be restored to parallel position at any time by running the rolls to the far down position and holding valve in lower position momentarily.

Valve arrangement - Special valve arrangement designed so rolls can be restored to parallel position at any time by running the rolls to the far down position and holding valve in lower position momentarily.

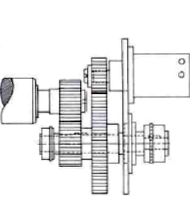

Hydraulic motor - Rolls are driven with a high quality, low speed, high torque hydraulic motor which positively transfers its power to the lower rolls through a drive train arrangement of spur gears running element type bearings.

Hydraulic motor - Rolls are driven with a high quality, low speed, high torque hydraulic motor which positively transfers its power to the lower rolls through a drive train arrangement of spur gears running element type bearings.

Top roll - The top roll is driven via a roller chain/torque limiter system to compensate for the difference of the inside and outside diameter of the work piece.

Top roll - The top roll is driven via a roller chain/torque limiter system to compensate for the difference of the inside and outside diameter of the work piece.

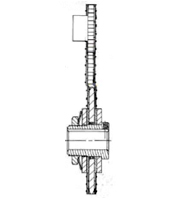

Adjustable roll position - indicated through a simple cable-pulley-spring arrangement with a pointer showing the position on a numbered dial.

Adjustable roll position - indicated through a simple cable-pulley-spring arrangement with a pointer showing the position on a numbered dial.

1 Electrical circuit - Only electrical circuit, which includes an emergency stop cable on 3 sides, is the 1 required to start and stop the prime mover (electric motor) that drives quite efficient hydraulic pump.

1 Electrical circuit - Only electrical circuit, which includes an emergency stop cable on 3 sides, is the 1 required to start and stop the prime mover (electric motor) that drives quite efficient hydraulic pump.

Hydraulic pump - quite efficient hydraulic pump, which gets its filtered oil from a large reservoir that is a structural part of the machine frame. This feature provides excellent heat dissipation and helps make a very cool running, efficient hydraulic system.

Hydraulic pump - quite efficient hydraulic pump, which gets its filtered oil from a large reservoir that is a structural part of the machine frame. This feature provides excellent heat dissipation and helps make a very cool running, efficient hydraulic system.

Functional design - To avoid the cost clutter and complexity of the electrically actuated hydraulic valves, we mounted a bank of manually operated directional valves on the main drive housing in a position which gives the operator a good view of the work area and the roll position indicators.

Functional design - To avoid the cost clutter and complexity of the electrically actuated hydraulic valves, we mounted a bank of manually operated directional valves on the main drive housing in a position which gives the operator a good view of the work area and the roll position indicators.

Speed control valve - To control the speed of the entire system, the oil is routed to the directional valves from the main pump through a speed control valve. The valve adjustment knob is conveniently located near the control station.

Speed control valve - To control the speed of the entire system, the oil is routed to the directional valves from the main pump through a speed control valve. The valve adjustment knob is conveniently located near the control station.

Frame - Housed the entire package in a robust, but compact, streamlined, fabricated and machines steel frame.

Frame - Housed the entire package in a robust, but compact, streamlined, fabricated and machines steel frame.