HYDRAULIC ANGLE + SECTION BENDING MACHINES

WDM

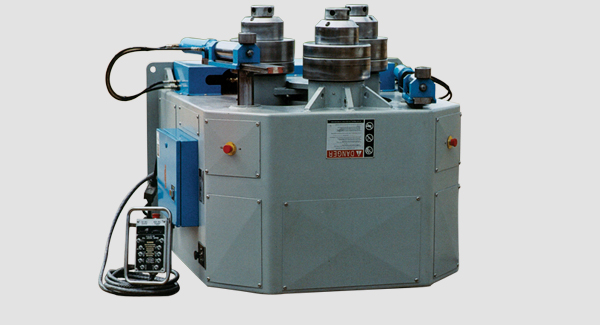

WDM Model AR-31 with 423-LP6 control

WDM Model AR-31 with 423-LP6 control

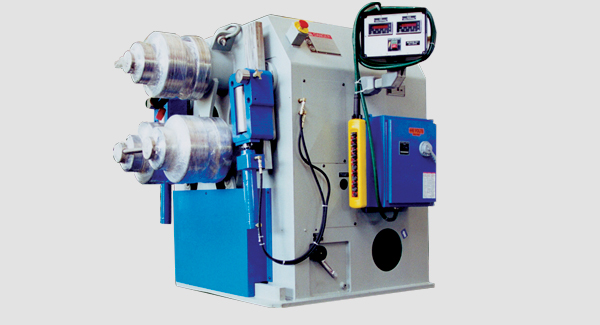

AR-41 with standard control in horizontal rolling position.

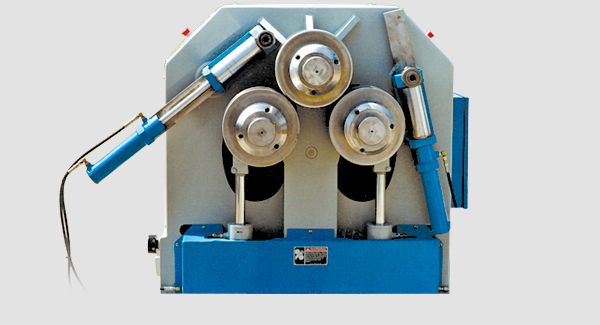

AR-50 packaged for shipment. Notice electrical enclosures and integrated hydraulic reservoir. Machine is setting in vertical rolling position.

AR-41 (vertical position)

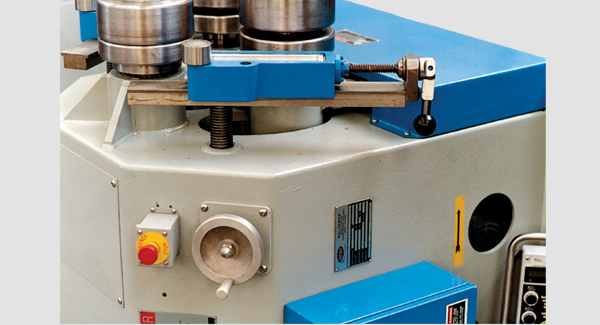

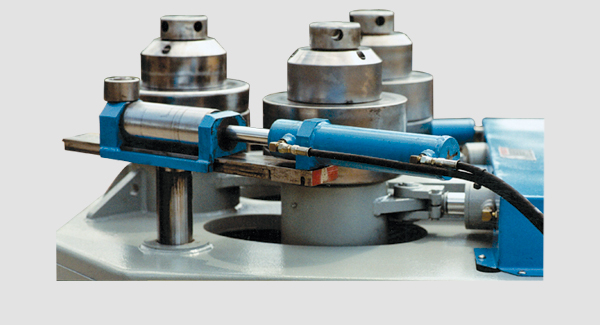

AR-31 - Guide roll area

AR-31 - Guide roll area

The frame is a weldment of heavy steel plates reinforced with gussets, braces, and bosses. After welding frame is accurately machined and fitted with non metallic lube-for-life type sleeve bearings.

The hydraulic system is integrated into the machine frame and is of efficient, quiet design. Depending on machine size rolls are either individually driven and hydraulically equalized or all driven by one motor and mechanically equalized. The electrical system is built to NFPA 79 specifications and housed in Nema 12 or better enclosures.

The roll shafts are heat treated alloy steel turning or SKF spherical roller bearings. The gears in the drive train most of which are cut in our own shop are heavy steel or alloy with a very strong tooth profile.

Guide roll systems, the key to successful angle bending. WDM machines have guide roll adjustment systems that allow the user to adjust the rolls in all ways necessary to obtain good work pieces. The small/economy machines have manual adjustments with clamps and jack screws. The large machines have handwheel/worm gear arrangements. Machines 4x4 and larger have 6 way power guide rolls for optimal performance.